PTFE with Silica Filler Gasketing

The GYLON® Style 3500 is a high performance, silica filled PTFE sheet material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media.

For oxygen service, specify “Style 3502 for oxygen service.”

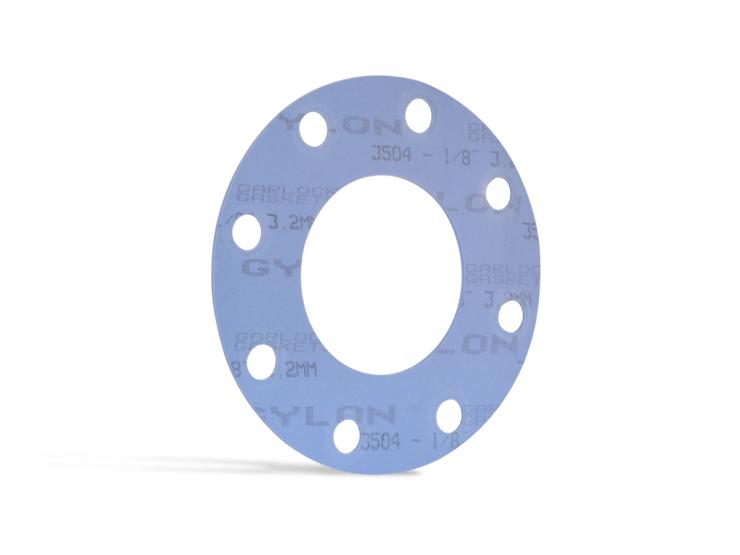

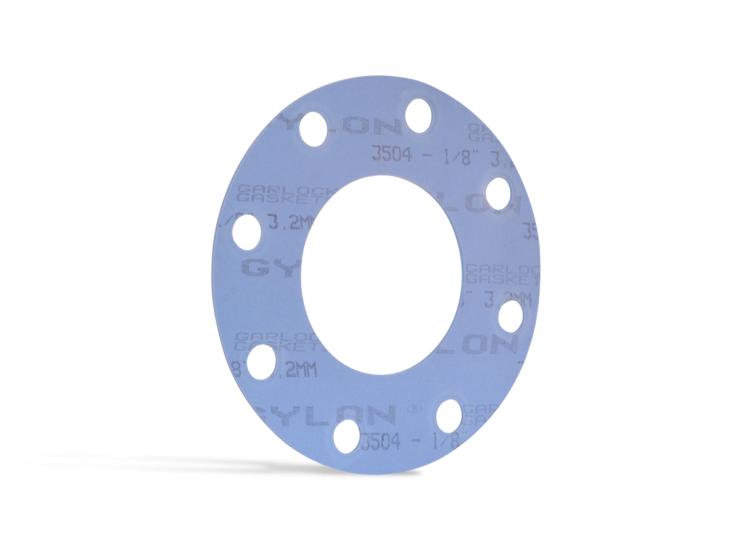

The GYLON® Style 3504 gasket is made of PTFE with aluminosilicate microspheres. It is designed for use in many acids, some caustics, hydrocarbons, refrigerants, and more.

For oxygen service, specify “Style 3505 for oxygen service.”

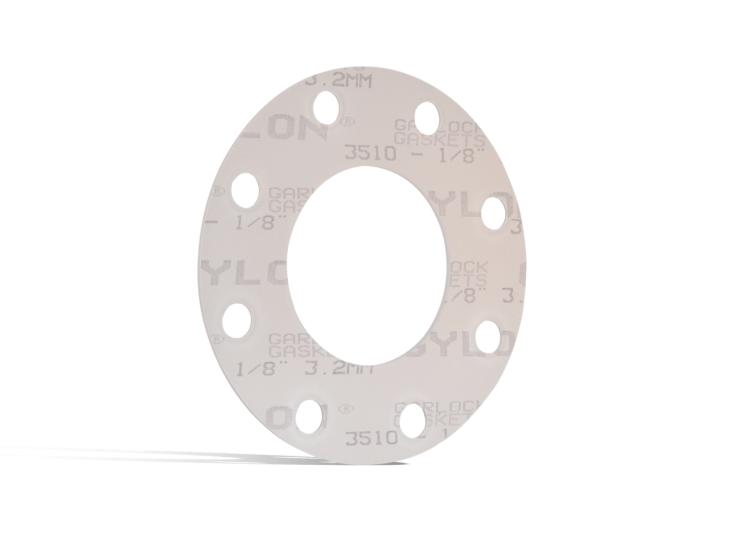

The GYLON® Style 3510 is a high performance, barium sulfate filled PTFE gasketing material. GYLON® 3510 PTFE gasket is designed for use in strong caustics and toxic chemicals, such as chlorine, ammonia, and phosgene, where initiating and maintaining an extremely tight seal is critical. In addition, the GYLON® 3510 provides exceptional performance in monomer services.

For oxygen service, specify “Style 3503 for oxygen service.”

The GYLON® Style 3535 joint sealant tape is made of solid PTFE. This joint sealant tape can withstand a wide range of chemicals and meets FDA regulations. Style 3535 is easy to cut and form, and the adhesive backing makes it easy to install on narrow and hard-to-reach flanges.

Double jacketed gaskets are constructed using one piece of metal to cover the bottom and edges of the soft sealing material, and an additional piece of metal to completely cover the face. Style 623 has good compressibility and resilience and is the most popular clad gasket manufactured

Ideal for corrosive applications with extra large flanges

Double jacketed gaskets are constructed using one piece of metal to cover the bottom and edges of the soft sealing material, and an additional piece of metal to completely cover the face. Style 623 has good compressibility and resilience and is the most popular clad gasket manufactured

Copyright © 2023 Erith, All Rights Reserved