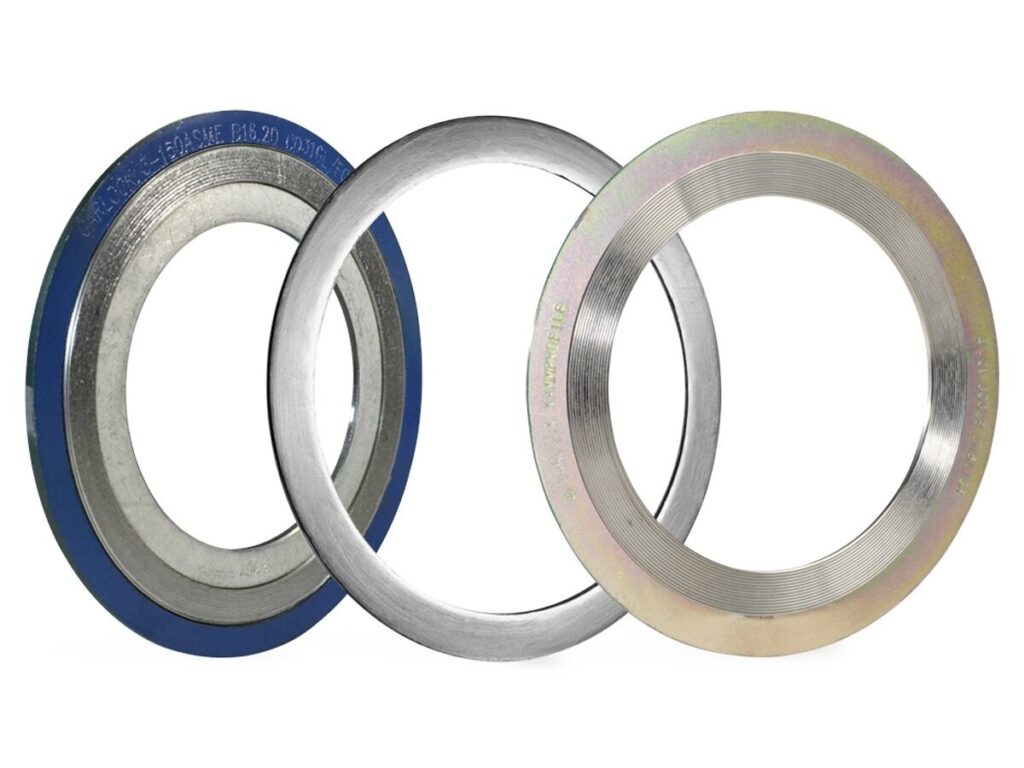

From extreme temperature or pressure applications to aggressive chemical exposure, there is a Garlock Metallic Gasket available for every application. Our Houston, TX manufacturing facility offers a wide range of Gaskets, including Spiral Wounds, Corrugated Metal Gaskets (CMG), and Kammprofile, all available in ASME and EN Standards or in customized configurations.

Available metals include common alloys such as 304L and 316L, as well as exotic materials, such as INCONEL®, HASTELLOY®, and MONEL®, all reliably stocked at our Houston warehouse thanks to strong ties with strategic suppliers. We also offer fillers and facing materials, including high-purity graphite grades, ePTFE, GYLON®, Mica, as well as Garlock’s groundbreaking high-temperature material: THERMa-PUR®. Our online catalog only includes our ASME Standard Gaskets. If you are looking for custom sizes, or you need support with a challenging application, contact us – we stand ready to help!

Copyright © 2023 Erith, All Rights Reserved