CNAF CONTENT TO DONE AND CNAF IMAGE TO RIGHT

Style 8400 flue ducts are available in round, rectangular, or square configurations; as belt type (without flanges) or U-type (flanged); with virtually no size restrictions. Garlock also provides on-site vulcanizations for flue ducts that require splicing into position, due to obstructions or interferences that prevent continuous construction installations.

Rectangular / Square Flue Ducts

Stanard face-to-face dimensions: typically 6in / 152 mm, 9in / 229 mm, or 12in / 305 mm

Contact Garlock for non-standard face-to-face dimensions and movement capabilities

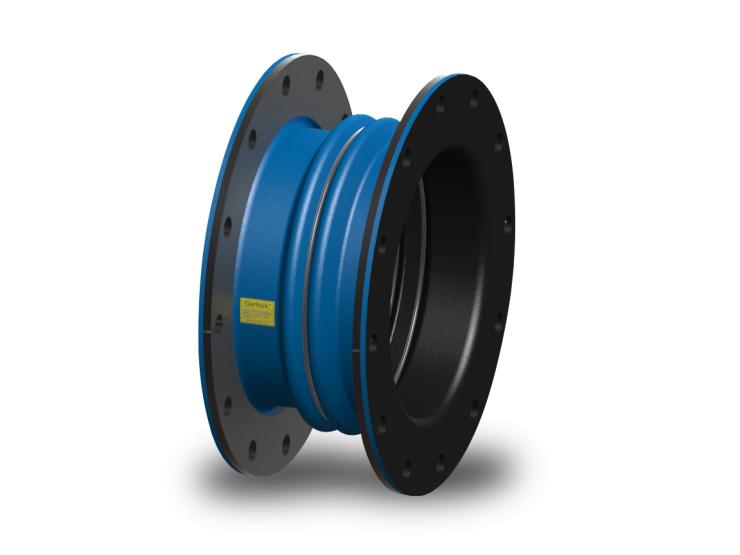

Round Flue Ducts

Supplied in any size, with or without flanges or arch

Variety of materials available: neoprene, chlorobutyl, fluoroeslastomer, nitrile, EPDM, CSM, FDA neoprene, FDA EPDM, or natural/gum rubber

Movement capabilities depend on expansion joint size and arch configuration

Belt-Type Flue Ducts

Supplied in any size, without flanges, with or without an arch

Available in the same materials as round flue ducts

Movement capabilities depend on installation width and arch configuration

Supplied open-ended (wraparound) or continuous to fit over ducting

Style 8420 Split™ is typically used in applications where small piping limits the use of flanged connections. An example of this includes vacuum pump inlets and outlets in pulp and paper applications. It is also used as a temporary repair for piping that has cracked. It can be provided in the split design or as a sleeved product. Adhesives kits are also available for easy installation.

Split design eliminates equipment disassembly, reducing costly downtime

Available in EPDM, nitrile and fluoroelastomer in sizes from 2in / 5cm to 24in / 61 cm

Can be customized for your application; contact Garlock with your specifications

Offered as split design or sleeved product

Adhesives kits are also available for easy installation

Clamps are not provided

This multi-convoluted, lightweight expansion joint is designed for low pressure applications that require significant amounts of movement, axially and/or laterally. Its low spring rates make it ideal for air handling, load cell, bin activators, vibrating bins, silos, and pellet/dough hopper applications.

ABRA-LINE™: +180°F (+80°C)<br>

ABRA-SHIELD®: +300°F (+150°C)<br>

Natural Rubber: +180°F (+80°C)<br>

GUARDIAN® FEP: +400°F (+205°C)<br>

FKM (Fluoroelastomer): +400°F (+205°C)<br>

CSM: +250°F (+120°C)<br>

SURE-TEC™ FDA EPDM +250°F (+120°C)<br>

EPDM/FDA EPDM: +300°F (+150°C)<br>

HNBR (Hydrogenated Nitrile): +300°F (+150°C)<br>

Nitrile/DETECTOMER® FDA Nitrile: +250°F (+120°C)<br>

Chlorobutyl (Standard): +250°F (+120°C)<br>

Neoprene/FDA Neoprene: +250°F (+120°C)<br>

Copyright © 2023 Erith, All Rights Reserved