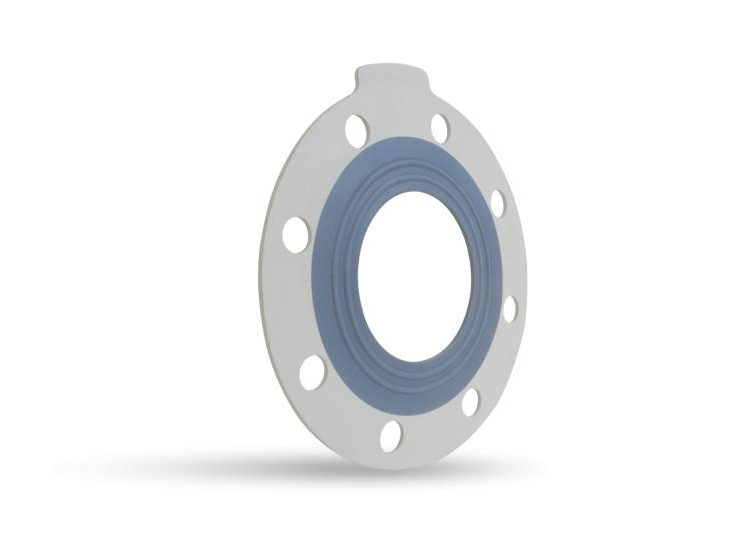

STRESS SAVER® 370 gaskets feature raised, molded-in sealing rings and seal with 75% less surface area for high performance in non-metallic flanges. Its pure PTFE sealing surface resists many chemicals and the contaminant-free EPDM body is ideal for a variety of high purity applications.

* Tested by BALASZ Labs for trace metal extractables, Anions, Cations, and T.O.C.s. Results available on request.

** Consult Garlock Applications Engineering for FDA information.

The STRESS SAVER® XP a blend of high performance fluoroelastomers, molded with the same rib configuration as the rest of the STRESS SAVER family of products. In addition, the STRESS SAVER XP is National Sanitation Foundation (NSF) Standard 61/372-certified for use in drinking water systems and carries the Lubrizol FBC™ System Compatible certification making it suitable for use in CORZAN (CPVC) Piping.

NSF 61/372 approved for use potable (drinking) water

FBC™ System Compatible indicates that this product has been tested, and is monitored on an ongoing basis, to assure its chemical compatibility with FlowGuard Gold®, BlazeMaster® and Corzan® piping systems and products made with TempRite® Technology. The FBC System Compatible Logo, FBC™, FlowGuard Gold®, BlazeMaster®, Corzan®, and TempRite® are trademarks of Lubrizol Advanced Materials, Inc. or its affiliates.

Manufactured from 100% pure PTFE and utilizing our proprietary GYLON® process, the 3545 TUFF-RAIL® gasket is specifically designed to help address those difficult installation and sealing requirements of manways. Formulated to compress and conform, the 3545 TUFF-RAIL® is easily installed with excellent load retention, maintaining a tight seal even during heavy vibration and thermal cycling. The patent pending technology incorporates raised ribs to insure the gasket performs under the limited bolt load and the narrow seating surface of the nozzle.

Not available in Europe

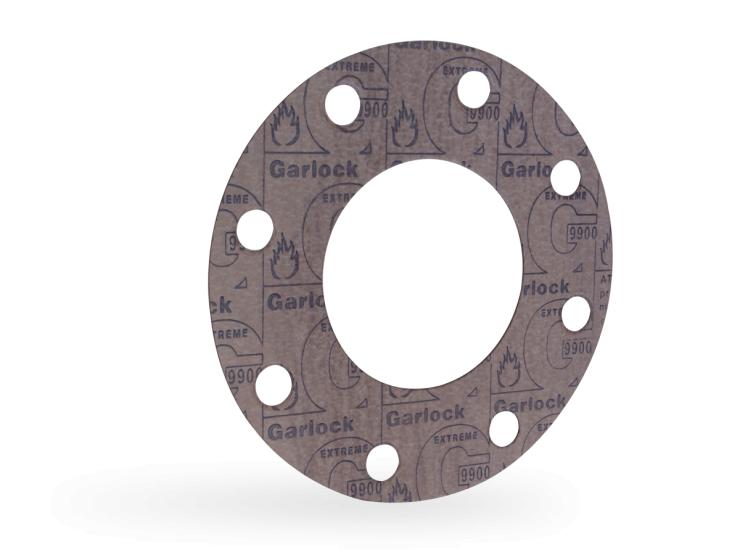

Style 9900 gasket is composed of graphite fibers with a nitrile binder, allowing it to withstand extreme conditions. This high temperature gasket has passed Garlock® fire tests and is ABS Fire Safe Type Approved.

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16″ strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig, consult Garlock® Engineering.

High Temperature Cut Gaskets and Sheets

THERMa-PUR® is yet another innovative sealing solution that provides more than just temperature resistance. Style 4122 is designed for use in high temperature sealing applications. It is produced using an environmentally friendly solvent-free process and combines a unique formulation with traditional quality. THERMa-PUR® out performed vermiculite based gaskets in laboratory testing, showing significantly less leakage even in extreme thermal cycling condition.

Typical Physical Properties

Copyright © 2023 Erith, All Rights Reserved